In the world of electronics and modern-day technology, the importance of printed circuit boards (PCBs) can not be overemphasized. A PCB, frequently referred to as a circuit board, provides the necessary framework for linking different electronic parts via conductive tracks etched onto non-conductive substratums. Among the numerous types of PCBs, the rigid-flex circuit boards stand out as an impressive innovation.

The production of PCBs, specifically in high-density interconnect (HDI) configurations, has developed as the need for smaller sized, quicker, and extra reliable electronics rises. HDI PCBs include finer lines and spaces, as well as smaller sized vias, which enable better part density. This is particularly important in today's hectic tech landscape where performance improvements are consistently pursued. To produce these sophisticated boards, companies commonly use sophisticated methods such as microvia modern technology, which involves creating very little vias with laser drilling techniques. The advantages of microvias consist of boosted signal speed and decreased electro-magnetic disturbance, thereby boosting the total performance of the electronic gadgets they support.

Collective ventures with printed circuit manufacturers are critical in making sure that PCB styles change smoothly from theoretical stages to real items. These manufacturers specialize in numerous aspects, consisting of PCB assembly and fabrication. They use products like FR-4, a flame-retardant epoxy resin, which is extensively related to for its balance of performance and cost-effectiveness. In the world of high-performance applications, variations such as Rogers material, Megtron 6, and Megtron 7 are regularly utilized for their premium dielectric properties and high-frequency efficiency. Subsequently, printed circuit card assembly (PCBA) becomes a crucial action in the process where numerous parts are soldered onto the PCB in exact arrangements to make certain optimal procedure.

Quick turnaround PCB prototyping services have actually gotten appeal as organizations aim to bring their items to market quickly. This active manufacturing technique enables companies to evaluate and validate their designs prior to devoting to complete production runs. Such prototyping is vital in minimizing time-to-market and enables repetitive enhancements based on first testing results. Suppliers use flexible choices for both low-volume and high-volume orders to suit diverse manufacturing demands. Moreover, with the increasing schedule of fast-turn PCB services, the barriers to prototype advancement have been dramatically reduced, enabling a setting of development.

Flexible printed circuit boards (FPCBs) are another amazing classification that has actually amassed focus due to their unique capabilities. These boards are designed to be lightweight and ultra-thin, offering the ability to bend, fold up, or spin without endangering efficiency.

Thermal management, for circumstances, plays a crucial function in PCB design, especially in electronic items that operate under high lots. Engineers should consider products with good thermal conductivity, such as heavy copper PCBs, which assist dissipate heat effectively.

The understanding of printed circuit card design is fundamental for designers and product designers. Learning regarding various elements such as circuit card assembly, that includes the process of soldering elements onto a PCB, can dramatically impact completion item's quality. Effective design techniques make sure that electrical pathways are maximized and that the overall design decreases disturbance, thereby enhancing life expectancies and efficiency. In addition, making use of devices and software developed for PCB design and simulation can drastically simplify the design process, allowing creators to promptly modify prototypes based upon testing results.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to certain applications based on their complexity and the variety of elements that need to be incorporated. Four-layer PCBs offer increased transmitting abilities, crucial for extra sophisticated electronics. These boards help in managing signal honesty and offer ample area to route traces better, making certain more dependable efficiency in everything from smart devices to complicated industrial tools.

Contract PCB assembly services have ended up being a vital resource for companies doing not have the in-house abilities to handle complicated assembly procedures. These services often consist of comprehensive assistance varying from design assessment to major production, providing services with the adaptability they need to meet differing needs. By partnering with established manufacturers, companies can take advantage of proficiency in areas such as HDI designs, microvias, and multilayer PCBs, therefore increasing their product offerings without spending greatly in tools and labor.

Choosing the right materials for PCB production is critical, and considerations typically consist of the ecological criteria applicable to their use, consisting of UL ratings, such as 94V-0, which relates to fire retardancy. Manufacturers need to stay notified regarding compliance policies to guarantee that their products meet safety standards while also carrying out optimally in their intended application environments.

The combination of radio frequency (RF) innovation into PCBs is one more area seeing enhanced relevance, especially with the rise of wireless communication devices. RF PCBs should be thoroughly developed, with considerations for resistance control and reduced signal loss due to the high regularities included. This expertise requires understanding of RF circuit design and may entail in-depth electromagnetic simulations as designers work to attain ideal functionality in portable kinds.

As innovation remains to progress, manufacturers are progressively taking on automation and advanced fabrication procedures to enhance performance. Technologies such as automated optical evaluation (AOI) and surface area mount modern technology (SMT) are now common practices, enabling high-speed assembly and regular quality assurance. Innovations in PCB manufacturing likewise encompass new products and methods, such as making use of embedded innovation where components are embedded straight within the layers of the PCB, further conserving room and improving efficiency.

In conclusion, the printed motherboard market continually adapts to transforming demands and technological improvements, reflecting the dynamic landscape of electronics. Whether with PCBA, flexible circuits, or fast-turn prototypes, the layouts, products, and procedures connected with PCBs are critical fit the future of electronic devices. Manufacturers who remain at the leading edge of these technologies not just boost their affordable edge but also enable the growth and development of sophisticated modern technologies that specify modern-day life. With the ever-increasing intricacy of circuits and the demand for efficient, high-performance solutions, the PCB sector continues to be a keystone of technical progress, driving the way we interact with devices and inevitably attaching our physical and digital globes.

Discover circuit board prototyping the essential duty of printed circuit card (PCBs) in contemporary electronics, from innovative rigid-flex layouts to high-density interconnects and fast-turn prototyping services, and uncover exactly how these technologies are forming the future of devices we make use of everyday.

Barret Oliver Then & Now!

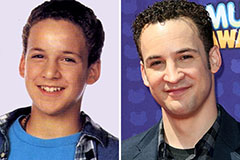

Barret Oliver Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!